Valley Meats

Mission Statement

To provide the safest protein products which meet or exceed our customers’ expectations as to quality and service in a sustainable and ethical manner.

History

Since the early 1970s, Valley Meats has been servicing its customer base from an ever-expanding facility in the Quad Cities region of Illinois and Iowa, which is ideally positioned in the heart of America’s beef and pork producing region. For most of our history, the majority of sales were of our branded J&B Meats product line, sold through foodservice distribution to casual and quick service restaurants, educational and healthcare facilities, hospitality and entertainment venues.

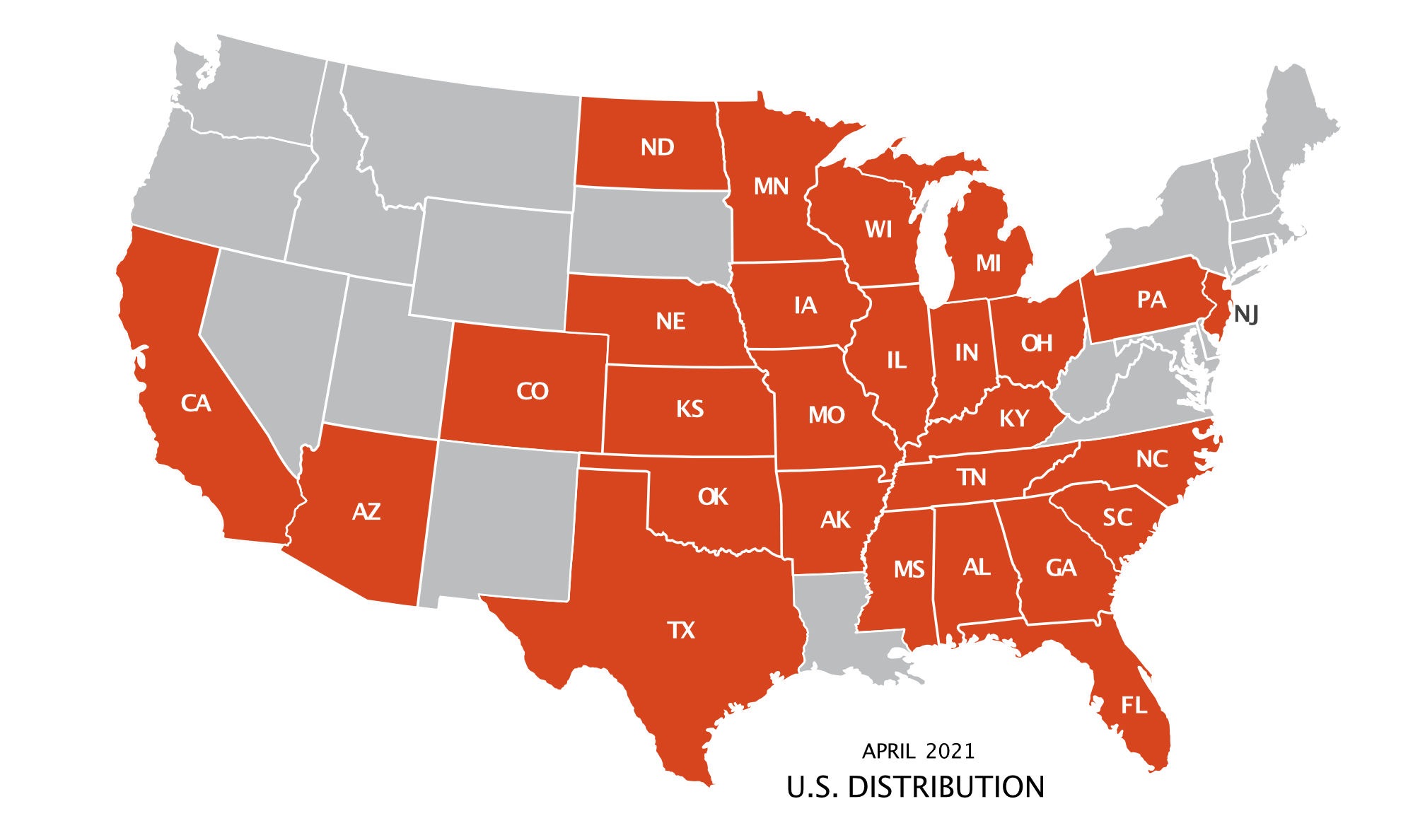

Over time, our custom formulation business has grown, now representing over 60% of our sales. We work closely with end user customers to formulate and process products customized to their needs and specifications. We are currently supplying custom formulations and J&B branded items in 27 states from coast to coast. The products highlighted in this brochure represent our J&B Meats product line, but they also reflect our broad formulating and processing capabilities.